Home > News

> News Information

Home > News

> News Information

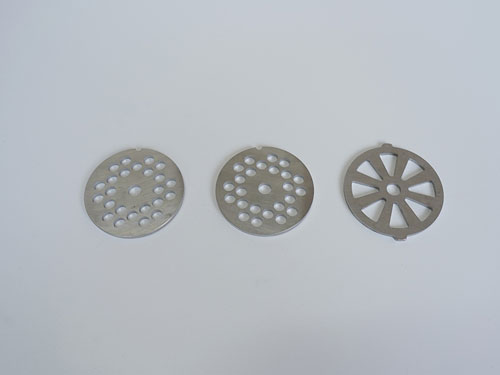

Meat grinder bladeThe reason why home meat grinders have become the new favorite household appliances in the kitchen is that the meat grinder blades can not only be used to crush meat, but also to crush foods such as peanuts, onions, garlic, spices, etc., making home meat grinders a food cooking machine that can be applied in more diverse scenarios.

The production and processing of meat milling blades mainly use milling methods, and the method to improve milling processing is to optimize the milling strategy of the face milling cutter. When programming to machine flat milling, users need to first consider the method of cutting the cutting tool into the meat milling blade workpiece. Usually, milling cutters are just a simple method of directly cutting into the workpiece. When the blade exits the cutting process, there is usually a significant impact noise caused by thick chips generated by the milling cutter. Due to the significant impact of the blade on the workpiece material of the meat grinding blade, it often causes vibration and generates tensile stress that can shorten the service life of the machining tool.

Another better cutting method is the rolling cutting method, which means that the milling cutter rolls into the meat cutting blade workpiece without reducing the feed rate and cutting speed. The programming radius of the tool path should be 1/2 of the milling cutter diameter, and the offset distance from the tool to the workpiece should be increased. This means that the milling cutter must rotate clockwise to ensure machining is done using the milling method. The chips formed in this way, from thick to thin, can reduce vibration and tensile stress acting on the tool, and more cutting heat can be transferred to the chips. By changing the method of cutting the milling cutter into the meat cutting blade workpiece each time, the tool life can be extended by 1-2 times.

Although the rolling cutting method is mainly used to improve the method of cutting into the meat cutting blade workpiece, the same machining principle can also be applied to other stages of milling.

.jpg)