Home > News

> News Information

Home > News

> News Information

currentlyMeat grinder discThe common production process used is stamping, which has a high degree of mechanization, good surface treatment, high standardization, and pays more attention to details. When choosing a meat grinder, please pay attention to the cutting edge of the blade. In terms of sharpness, steel has a higher hardness, the degree of cutting edge is smaller, and the curvature of the cutting edge is softer. The cutting edge of a good meat grinder should be straight and without gaps.

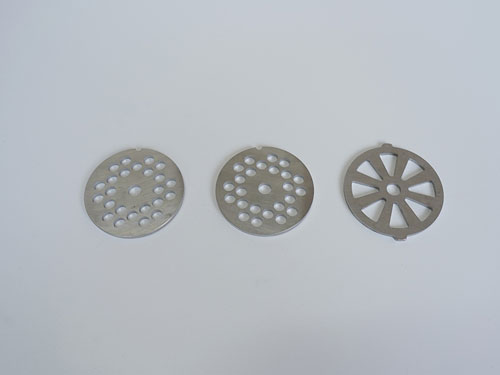

The meat grinder disc has multiple cutting blades with different functions and shapes, as well as a thickness adjustment device. It can not only conveniently adjust the width, thickness, and length, but also cut various shapes through the combination of different shaped cutting blades. With the widespread use of meat grinders, we may encounter the situation of purchasing meat grinders. So, what are the methods for selecting meat grinders? What are the precautions for selecting a meat grinder disc?

.jpg)

Precautions during the process of selecting a meat grinder:

1. Anyone who has used a meat grinder knows that the higher the hardness, the sharper it is. The "speed" of the meat grinder also depends on the degree and softness of the blade edge. The sharper the blade, the easier it is to grind meat. At present, there are various types of meat grinders on the market, so when choosing a meat grinder, it is important to check whether the blade is sharp, straight, and has no gaps.

2. According to the processing technology, the commonly used production process for meat cutting discs is stamping. Simply put, a complete meat cutting disc is made by directly stamping a large steel plate with a punching tool, and then going through subsequent processes such as cutting edge, surface treatment, and heat treatment to produce the finished product. Stamped meat cutter discs have the advantages of high efficiency, high cost, high mechanization, good surface treatment, high standardization, and more attention to details.

3. Looking at the cutting edge of the minced meat cutter, in terms of sharpness, steel has higher hardness, the degree of cutting edge is smaller, and the curvature of the cutting edge is softer. The cutting edge of a good meat cutter requires straightness and no gaps.

4. The thickness of the meat grinder disc is also important. The thinner the knife, the sharper the blade.

.jpg)