Home > News

> News Information

Home > News

> News Information

1. Standard parts and specifications

The selection method of standard specifications for molds should consider the following: (A) In the case where the specifications used are not limited, it is best to use the highest level. (B) In principle, standard numbers are used. (C) If the standard parts of the mold do not have this size, the nearest one should be used for processing.

2. Design of the punch

According to its function, the punch can be roughly divided into three parts: (A) the cutting edge tip of the processed material (the cutting edge shape can be irregular, square, circular, etc.). (B) The contact part with the punch fixing plate (fixed part or handle part with irregular, square, circular cross-sectional shape, etc.). (C) The connecting part (middle part) between the blade and the handle.

This article briefly describes the design criteria for each part of the punch, including (A) the length of the cutting edge, (B) the grinding direction of the cutting edge, (C) the fixing method of the punch, and the shape of the handle.

(1) Cutting edge length: The design of the cutting edge length of the stage punch should consider that there will be no lateral bending during processing, and the gap with the moving part of the pressing plate should be appropriate. The relationship between the pressure plate and the cutting edge of the punch is guided and non guided, and the straight length of the cutting edge will vary.

(2) The grinding direction of the cutting edge: The grinding direction of the cutting edge can be parallel to the axis (upward cutting) or perpendicular to the axis (through cutting), and the former should be used to improve the wear resistance and burn resistance of the punch. When the shape of the cutting edge is convex, it can be cut through, and when it is concave convex, it can be processed by upper cutting or through cutting in combination.

(3) The fixing method of the punch and the shape of the handle: The handle of the punch can be roughly divided into two types: straight section and shoulder type. The selection factors of the fixing method include the accuracy of the product and mold, the processing machinery, processing method, maintenance method, etc. of the punch and punch fixing plate.

(4) The size and accuracy of the handle: Depending on the method of fixing the punch, there may be different requirements for the size and accuracy of the punch handle.

(5) Adjustment method for punch length: Due to re grinding, the length of the punching punch is shortened, so it is necessary to adjust the punch length to maintain balance with the punch length of other projects, such as bending, stretching, etc., and to maintain the design length of the punch.

(6) Design of punch in conjunction with stamping processing: In order to achieve quality and safety of stamping products in mass production and prevent defective products, the following considerations need to be taken into account in terms of molds: A. The grinding direction of punch processing should be consistent, and the surface should be polished. B、 To prevent chips from floating up, a top pin or air hole can be installed on the punch. C、 In order to reduce the impact force, the punching punch should have oblique processing, and the small punch near the large punch should be shorter to reduce the impact force.

(7) Punch design and processing method: The shape design of the punch is absolutely related to the difficulty of processing. When the distance is too close, the processing of the punch fixing plate becomes difficult. At this point, the punch should be divided and processed (using a combination method).

3. Design of punch press fixed plate

The thickness of the punch fixing plate is related to the size of the mold and the load, generally 30-40% of the punch length. The length of the punch guide should be 1.5 times higher than the punch diameter.

4. Design of guide pin (punch)

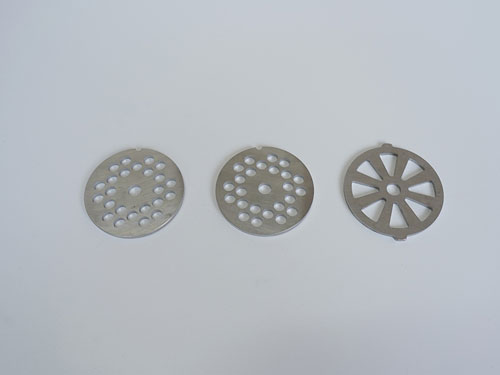

The diameter of the guide pin (punch) guide part and the gap between the material guide hole, its size, and the amount protruding from the pressure plate are designed according to the thickness of the material. The shape of the guide pin tip can be roughly divided into two types: A. projectile shape; B. Conical shape (push-pull shape).

(1) The shape of a shell is a common form, and there are standard parts on the market.

(2) The conical shape has a certain angle and is very suitable for high-speed stamping of small parts. The determining factors of the pushing and pulling angle are the stamping stroke, the material of the workpiece, the size of the guide hole, and the machining speed. When the pushing and pulling angle is large, it is easier to correct the position of the processed material, but the length of the pushing and pulling part will become longer. The joint between the push-pull part and the cylindrical part should be smooth.

5. Design of master mold

(1) Design of cutting die

The key factors to consider in the shape design of the punching die include: A. mold life and the shape of the escape angle; B. Cutting corners of the master mold; C. The segmentation of the master model.

(A) The lifespan of the mold and the shape of the escape angle: This design is very important. If not designed correctly, it can lead to poor stamping processing such as damage to the punch, blockage or floating of chips, and the occurrence of burrs.

(B) Cutting angle of mother mold: In order to reduce the punching force during shape punching, the mother mold can be designed as a cutting angle. When the cutting angle is large, the punching force is also greatly reduced, but it is easy to cause product bending deformation.

(C) The segmentation of the master mold: The master mold must undergo precision processing such as molding and polishing. Due to its concave surface, it is difficult for polishing tools to enter, so segmentation is necessary.

(2) Design of bending master mold

In the design of the master mold for bending processing, in order to prevent phenomena such as rebound and excessive bending, the part shape of the master mold for U-shaped bending processing is a combination of double R and straight parts (with a slope of 30 degrees), preferably approximating an R shape. The shape of R parts should be polished after forming grinding or NC discharge machining.

(3) Design of Extended Mother Mold

The shape of the corners and escape corners of the extended master mold are important design issues. The shapes and characteristics of the corners and escape corners are as follows: when the angle value of the extended master mold R is large, it is easier to extend the product, but it can also cause wrinkles on the surface of the extended product, and the thickness of the side wall of the extended part is greater than that of the plate. When drawing thick plates and it is difficult to push them out, the R value of the master mold should be small, about 1-2 times the thickness of the plate. Generally speaking, the drawing part of the master mold for the upper cylinder and square cylinder is mostly made into a straight section. To prevent damage to the lubricating oil film during combustion and reduce the pushing force, there should be an escape part (stage shaped or push-pull shaped) design below the straight section. Especially in the case of shrinkage machining, it is necessary to minimize the number of straight sections as much as possible.

6. Countermeasures for lateral pressure of punch

When stamping, the optimal ideal state is for the punch to bear equal loads on both sides (i.e. zero lateral pressure). When the punch bears lateral pressure, the upper and lower molds will be laterally offset, resulting in uneven gaps between the molds, which cannot achieve high-precision stamping. There are the following measures for punch side pressure: (a) changing the processing direction; (b) Products processed on one side (such as punching, bending, drawing, etc.) are arranged in two rows; (c) The punch or master mold is equipped with a side pressure block, and the side of the cutting edge is equipped with a guide part (especially for cutting and slitting processing).

7. Design of pressure plate

The function of the pressure plate is to strip the material applied to the punch and guide the action of the small punch. Its design content varies greatly depending on its different functions. According to the product design, the thickness and selection criteria of the pressure plate are as follows: 1) movable pressure plate; 2) Fixed pressure plate.

The gap between the pressing plate and the punch should be less than half of the mold gap (especially for precision continuous molds, this principle should be followed). When designing the pressure plate, it should be replaced according to different products, and the following precautions should be taken:

a. The gap between the pressure plate and the punch, as well as the length of the punch guide.

b. Installation standards for auxiliary guide columns and pressure plates, as well as escape design for pressure plates.

c. Measures to prevent the tilting of movable press plates during stamping processing.

d. The dimensional relationship between the guide pin holes of the fixed guide plate and the pressure plate.

e. The relationship between the material guide part of the fixed pressure plate and the width of the processed material.

8. Design of Back Pressure Plate

During stamping processing, the main components (punch, press plate, master mold) will bear surface pressure. When the punch pressure is higher than the surface pressure, a back pressure plate (especially the back of the punch and master mold sleeve) should be used. The use of the back pressure plate can be done in two ways: partial use and full use.

.jpg)