Home > News

> News Information

Home > News

> News Information

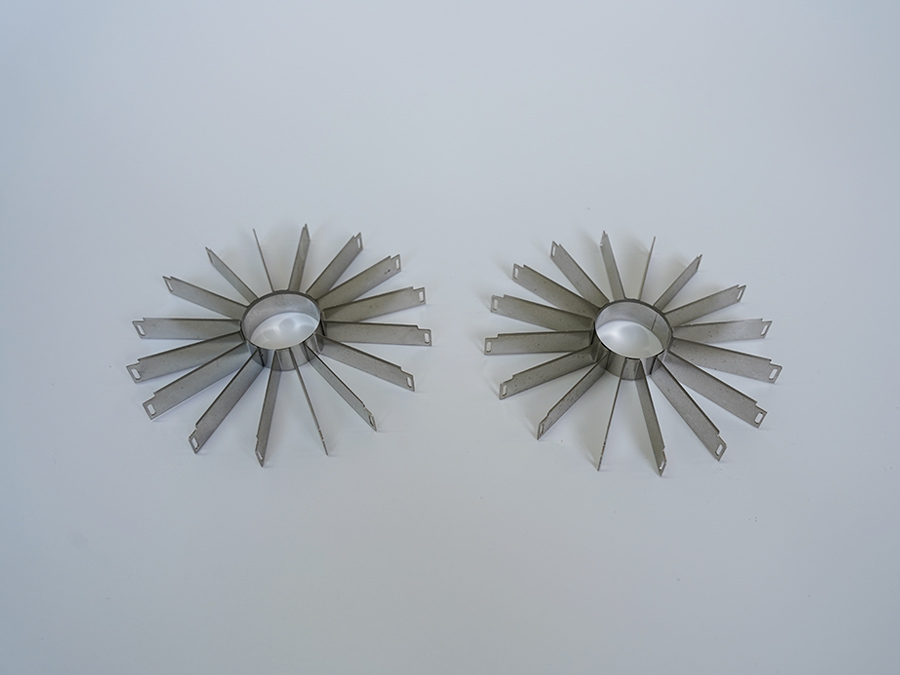

The burrs on metal stamping parts are usually considered inevitable, so in people's minds, burrs exist as long as the stamping parts are stamped. In fact, burrs also have their allowable range:

1. Stamping parts require burr length to be less than 10% of the sheet metal thickness;

2. Burrs that do not affect the degree of welding edge bonding;

3. Burrs that are not likely to cause personal injury;

Stamping may not affect the positioning and assembly of parts due to burrs.

.jpg)